Optimal utilization of energy

Big fuel savings

Quiet on electric drive. Good for the crew and the surrounding environment

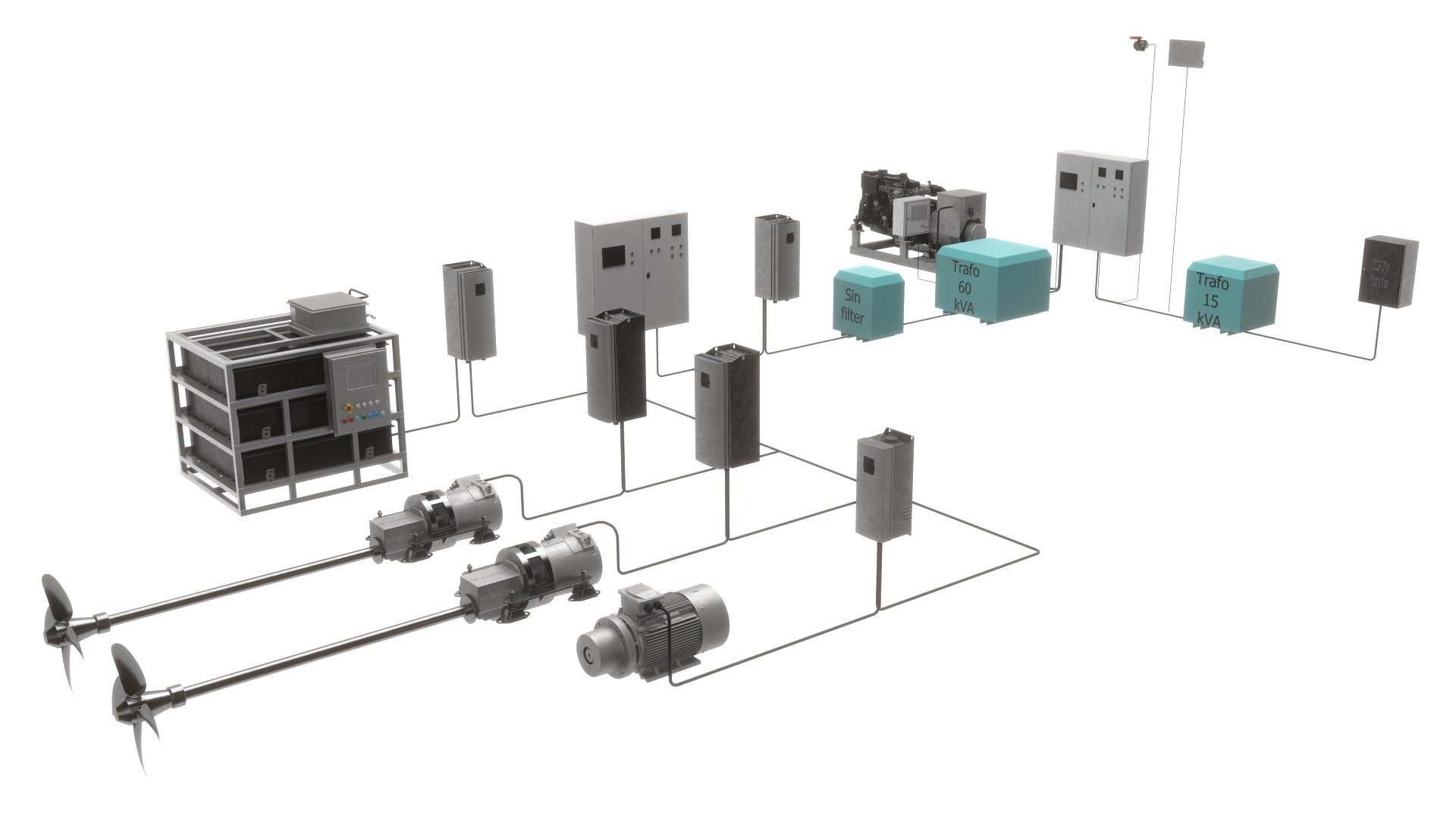

The system is adapted for workboats used in the aquaculture industry.

In the effort to reduce Norwegian domestic shipping's total emissions, Frydenbø, together with strategic partners, has developed a unique hybrid solution for smaller vessels. To reduce the costs of "changing" engines, the solution is designed so that there is no need to move or change existing diesel engines or axle systems in the vessel.

Inline Hybrid

Frydenbø hybrid power generation ensures optimal utilization of energy and provides major savings in fuel costs. Reduced operating hours and maximum utilization of engine efficiency also provide savings in terms of extended service life - as well as reduced costs related to service and maintenance of the conventional diesel engine.

Facts

- The electric motor has been specially selected due to its high operational reliability and efficiency. At the same time, it has also been a priority for us that the electric motor is on the same shaft as the diesel engine (inline), so that you as the user experience the transition from diesel to electric operation as seamless as possible. A consequence of the integrated electric motor is also that it has become a very compact system. This in turn gives boat builders and designers increased options in terms of configuration and the stability of the vessel.

- If we take the example of a vessel that is in operation 250 days a year and with a daily engine operation of 6 hours, our measurements show that one can reduce fuel consumption by 52%! This corresponds to a reduction in CO2 equivalents per year of 123,061 kg. In addition to a significant reduction in fuel costs and CO2 equivalents, we also see that the maintenance costs per year, compared to a traditional diesel engine, are reduced by 30%.

Talk to us about the Dual Drive hybrid system

We have dedicated staff to help you with your challenges and questions.